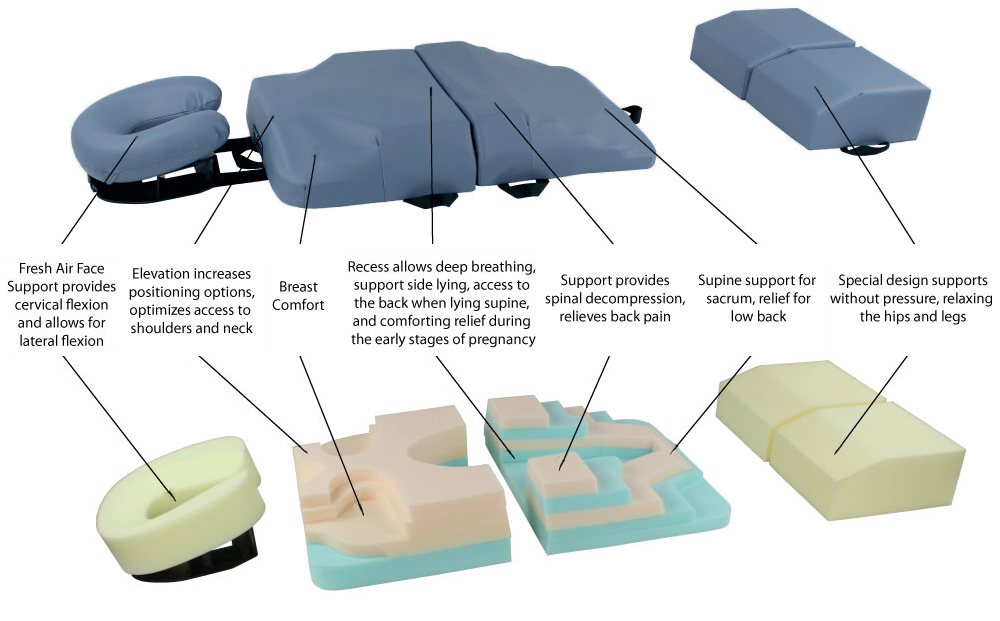

bodyCushion products are handcrafted of the most appropriate, highest quality materials available in the world today.

Vinyl

The vinyl used as a covering for the bodyCushion and its accessorizing products is the most durable, supple vinyl available. It is extremely abrasion and puncture-resistant and withstands repeated cleanings. This special vinyl assures excellent performance, strength, and durability in demanding medical and healthcare environments.

Foam

The complex foam construction of the bodyCushion is proprietary. Long-lasting, high-quality, non-toxic, odor-free foams provide positive elevation of support while affording optimal comfort.

Thread

The thread used to sew the bodyCushion and related products is a thread often used for sailboat sails. It is strong and is highly resistant to abrasion, UV, bleach, mildew, and rot.

Face Support Base

The “Fresh Air” bodyCushion Face Support Base provides extremely durable support for the Face Crescent. Thermoplastic construction is known for its toughness. Approximately 15 degrees of flexion for the neck is established. Generous openings on all sides optimize airflow.

Warning:

Be advised!

If you are reading this and contemplating manufacturing a look-a-like bodyCushion “knock off,” be advised that Body Support Systems, Inc is litigious and will fully exercise its legal protection rights as having been established in the Fifth District Federal Court of the United States of America.

Legal protection for the bodyCushion has been established by prevailing in a lawsuit brought by Body Support Systems, Inc. This lawsuit can be viewed online; BodySupport Systems, Inc. vs. Blue Ridge Table Company.

We at Body Support Systems, Inc. have been educating about positioning with the bodyCushion for more than thirty years and will not take kindly to anyone who may wish to take advantage of all of our hard work and effort since the inception of the bodyCushion.

Hereby be advised, if you attempt to bring to market a look-a-like product with characteristics similar to the bodyCushion, you will be sued in Federal Court with maximum damages and penalties sought.

Tom Owens, President, Body Support Systems, Inc

Inventor and developer of the bodyCushion